Textile Industry in the Vale of Leven

For the many people in the Vale of Leven, born after the last of the Vale textile Works closed in 1960, it may be difficult to visualise the quiet stretch of river from Balloch to Renton as one of the world's leading producers of bleached, dyed and printed cloth. It is certain however, that without more than 250 years of continuous textile processing on the Leven, the urbanised, industrialised communities which make up the Vale of Leven, would not be here today.

First in Scotland

Cloth processing came to the Leven long before Industrial Revolution. Six years before the birth of Tobias Smollett at Dalquhurn House, bleaching of linen was being carried out there by Andrew Johnstone in 1715. The bleachfields at Dalquhurn were the first established in Scotland, in what was for many years a summer only activity. Sour milk, water and sunlight were the bleaching ingredients with seasonal workers from Argyll a source of cheap labour. By 1728 Walter Stirling and Archibald Buchannan had established the Dalquhurn Bleaching Co. which with government subsidy, had extended the bleachfields - a mass of narrow canals of water, and beech hedges for shelter - to more than twelve acres.

During the next forty years, while there were advances in bleaching techniques, not least the use of Sulphuric Acid as a bleaching agent,

bleaching of cloth stopped being an end in itself and became the first step in a process that also involved dyeing and printing. In 1770 William Stirling, nephew of Walter Stirling, moved his printworks from Dawsholm on the Kelvin at Maryhill, to Renton. The attraction of clean air, clean fast water and cheap labour were too good to miss for a man whose family were well respected

Glasgow merchants. Through expansion and feuing William Stirling and Co. built Cordale Printworks, the Works at Dalquhurn and later Croftengea.

Printing

Prior to 1783 printing was largely block printing. Designs were hand carved in a block of wood, or sculptured with copper and brass strips. The printer would place the print pasted block on the cloth and repeat the process until a complete pattern was produced. In 1783 Thomas Bell devised a method of using a copper cylinder with the pattern engraved. By the middle of the next century this method had largely replaced block printing, although it was 1846 before the first five-coloured printing machine was erected at Cordale Works. Despite its slower speed, block printing overlapped the new system for many years and unlike the roller method is still used today on expensive, exclusive, short-run orders.

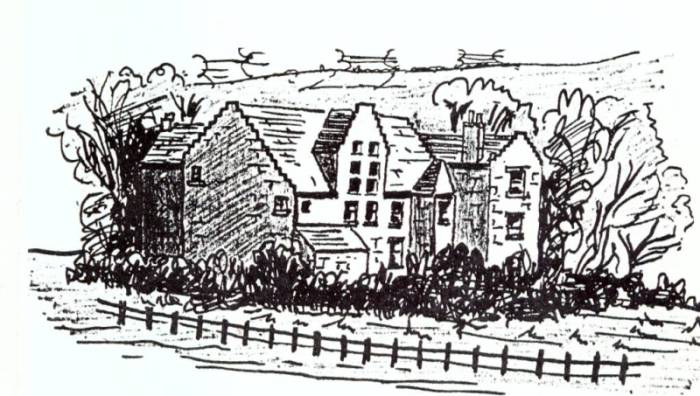

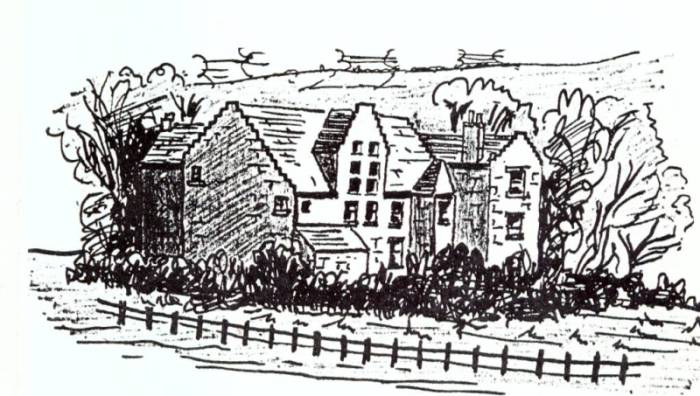

Place of Bonhill Renton

Matthew Turnbull was manager of Cordale works until 1859. He was the cousin of my great great grandfather. My branch of the Turnbull family moved from Renton via Kilbarchan, to Bridgeton after 1823. They were still active in the Block Printing and Calico printing, the last being my great grandfather Matthew Turnbull. Below is the Gravestone of Matthew Turnbull of the Cordale works and some of his family. They are buried in the Millburn Churchyard Renton.